| Environmental, Safety, Health and Energy(ESH&En) Policy | ||||||||

| TSEC is a highly professional manufacturer of solar cells and modules; in addition to pursuing corporate growth, TSEC values the prevention of pollution, the mitigation and adaptation of climate change, biodiversity and ecological conservation, promotes renewable energy, and enhances environmental performance by using sustainable resources. We also strive to improve the safety and health work rules to prevent the injury and ill health from occurring, observe or surmount relevant ESH&En laws and obligation, consulting with the company related workers, the contractors, and the interested parties. We pledge to integrate the information and resources to implement the following ESH&En policy in order to fulfill our social responsibilities and reach the goal of sustainable growth. | ||||||||

|

||||||||

|

||||||||

| Safety Education & Training | ||||||

| A company’s employees are one of its most important assets. Employees who have acquired safety awareness at work will take this awareness home with them, thereby helping to ensure safety at home. The resulting support from the employee’s family will encourage employees to make a greater effort to spread proper safety concepts in the workplace, creating a synergistic effect whereby individual employees, contractors, visitors and suppliers all come to attach more importance to health and safety issues. | ||||||

| Safety education and training is the means whereby a company inculcates safety concepts and awareness in its employees. For this reason, we take safety education and training very seriously. | ||||||

|

Safety education and training for employees |

||||||

|

||||||

|

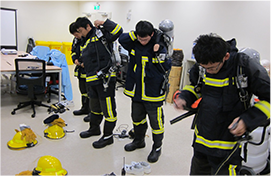

Skills training for Emergency Response Team (ERT) members |

||||||

|

||||||

|

Contractors’ personnel visiting our facility for safety training

|

||||||

|

| Emergency Response | ||||||

| There is an old saying that “if you want to be able to do a good job, you need to look after your tools properly.” To ensure safety within the factory area, prevent emergencies from occurring, and keep emergencies under control in the event that they do occur, suitable preparations need to be taken and the necessary facilities put in place to minimize damage and loss. At our factory, the following facilities and systems have been put in place to achieve the company’s disaster prevention and control objectives: | ||||||

|

||||||

|